You’ve Heard About It

3D printing has long been a dream of many. You have an idea, you use a computer, and suddenly, *bam,* you have a finished product right in front of your eyes. But is it really as easy as that?

Have 3D printers revolutionized product development for hobbyists, tinkerers, designers, engineers, or manufacturers? The resounding answer to that question is “yes, but…” That slight reservation is something that I have come to learn to the nth degree when building products and helping many others do the same. Let me explain.

You Want to Make Something

You’ve got this awesome idea that’s going to change the world, make you your first million, or fix that one specific problem that you and many others have. To that, I can only say maybe; let’s find out.

At this general inflection point, many think that 3D printing is here to make all their dreams come true, but only have some of the information, usually only marketing points. There are many misconceptions about 3D printing out there for product development, and it’s important to know just what to expect from consumer and locally accessible printers.

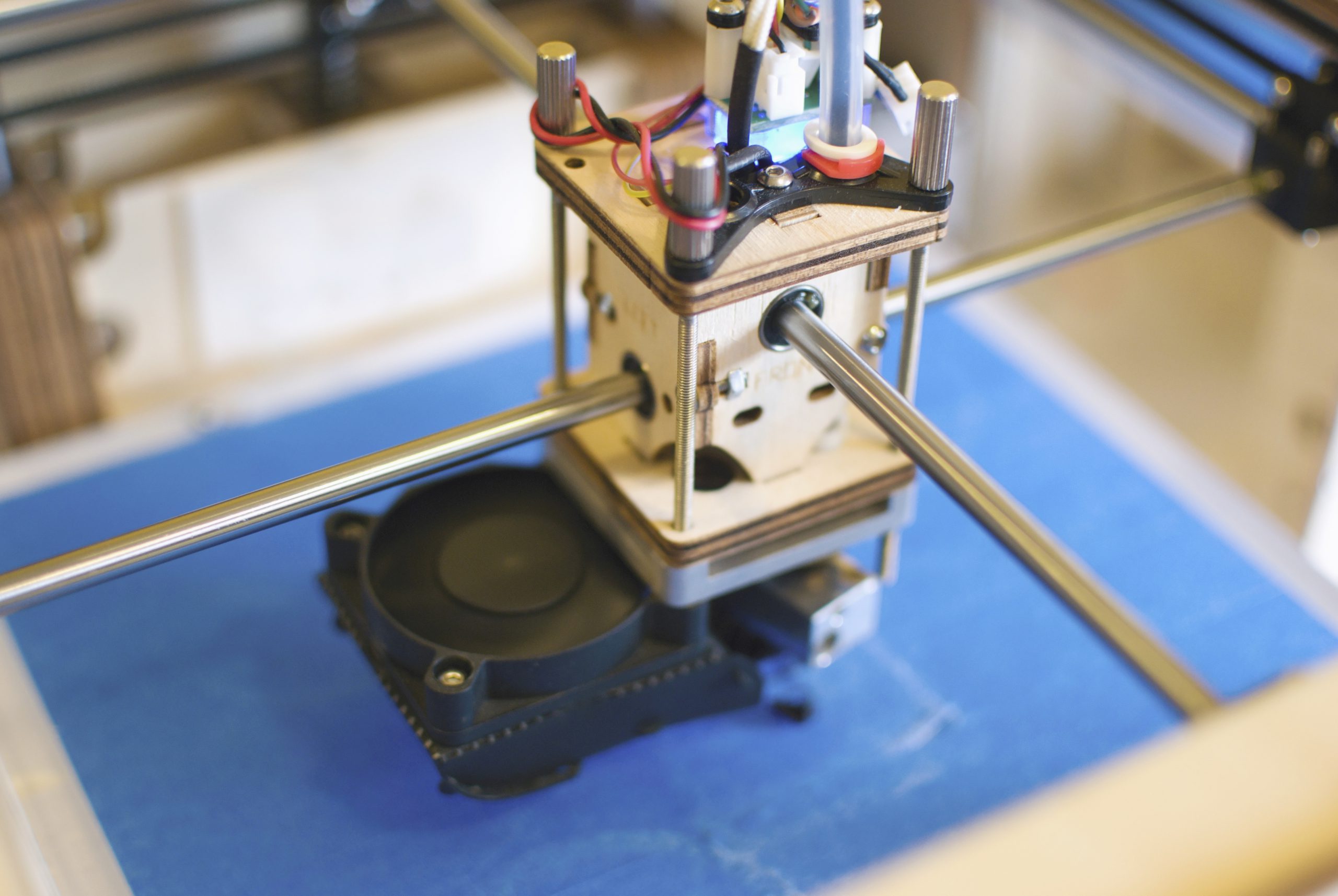

While types of 3D printers vary, (metal, plastic, clay, sugar, and polymer), most of us do not have access to 90% of what we read about. The majority of us have access to only the consumer-grade 3D printers. We generally have access to printers made and sold by the well known MakerBot, and many lesser known companies including RepRap, PrintBot, Tronxy, etc. These printers’ output varies wildly in quality, from low quality to precision, but they are mostly limited to plastic materials.

If your idea, your thing, is to be a usable working finished product, then you need to be A-OK with it being plastic, and any and all limitations that carry with it. This is the reality for most people with access to 3D printers.

Beyond Prototype

Access to 3D printers is the best tool to help those of us with limited hand-building skills develop a product prototype, one-off thing, or niché object difficult to monetize. In general, if your idea can be realized within the volume of a 6” cube space, then a plastic prototype may be good for you. Even the lower end of 3D plastic printers will allow you to realize a functional solid single (or limited) component object.

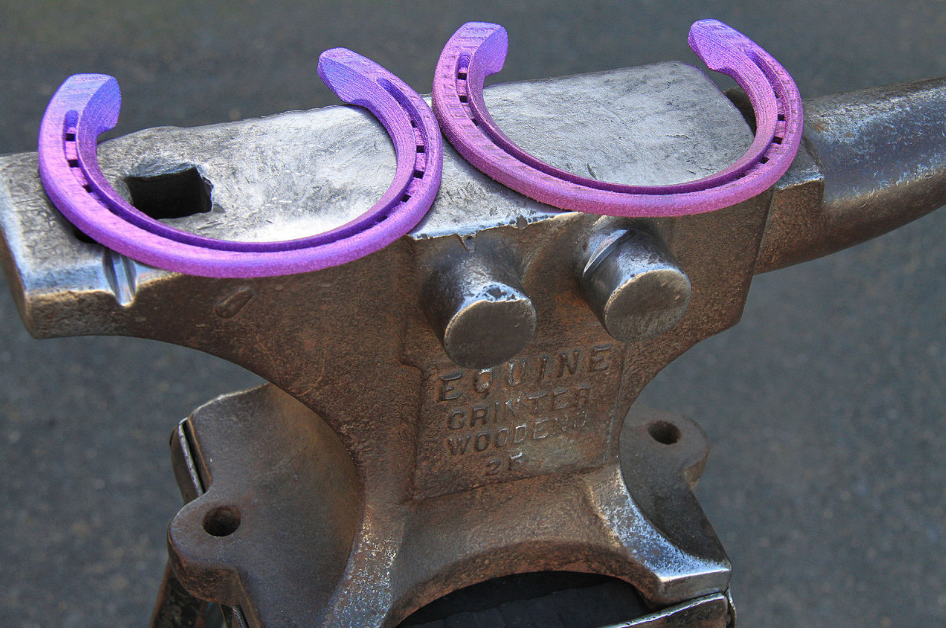

However, the 3D prints rarely produce the finished product. You will want

to either finish the plastic, or use this as the basis for a mold, version 2 prototype, or prop for future versions to be manufactured. Prints are regularly designed for manufacturing, i.e. translated to be made by other tooling, into either wood, metal, resin, or other material.

If you’re just getting into 3D printing, or are content with a plastic object, there are things you can do to up your product quality, you can do the following:

Select the best filament types

There are a wide range of filament types, ranging from rubber-like materials to glow-in-the-dark plastics, to consumer-grade ABS, to lego-brick-like PLA. There are many vendors and materials out there, but just be sure to choose the right filament size for your print nozzle, and be sure the material will withstand relevant product handling.

Provide the best finish

After you print, did you know you can finish it? Smooth those rough edges, sharp corners, and thick layer protrusions. Find some extremely low-grit sand paper (or sponge), and have at it. Just beware any thin or delicate parts of your print, and be sure to take extra time smoothing where any support or rafting material connected.

Prime and Paint

After you’ve sanded, you can even finish the print further by priming and painting it. Spending a little extra time on priming and controlled, evenly distributed, spray paint passes makes a huge difference in how your product looks. Be sure to start and finish your spraying off of the model for best results.

Good Ideas Are Hard

While I generally think 3D printing is a good idea for those of us with limited hand-building skills, and those of us who can work a computer aided design program, it’s not a magic bullet by any means. 3D printing, like any fabrication process, has its limitations. So long as you’re A-OK with plastics, and sizing, I think 3D printing is a good idea.

About LIGHTS: Ohio University’s Innovation Center founded the LIGHTS (Leveraging Innovation Gateways and Hubs Toward Sustainability) program in 2016. LIGHTS’ Innovation Network catalyzes the creation of companies to create high-wage jobs, and attract greater private investment in the coal-impacted regions of Ohio, West Virginia, and Kentucky. The Appalachian Regional Commission generously funded the program because of its unique way of matching complex problems and opportunities facing corporations, communities, and individuals to a network of two strategically-placed Innovation Hubs and seven Gateways. New marketable products arise from these problems. The Gateways and Hubs are new business incubators and makerspaces serving a 28-county area.