When I hear people talk about ‘cool’ tools at makerspaces and in community-accessible shops, 3D printers are the #1 mentioned device, hands down. While 3D printers are cool and have tons of use cases, they lack in one particular area: time. 3D printers are slow; laser cutters are not!

Let me be the first to advocate for the underrepresented laser cutter. You should have already heard about it. You should have tried it. However, if you are here now, let me tell you more.

Laser cutters are the ideal makerspace tool for attracting new members, giving demos, and building workshops with physical outcomes. They are quick, they are quiet, and they are relatively clean.

Attracting New Members

Laser cutters are ideal for attracting new members to your makerspace or organization. They are the best tool to ‘wow’ anyone with only a simple pattern, and you hitting the star button. With only a few choice pre set patterns saved to the machine, you can show walk-ins and tours the ropes in under two minutes. Once a prospect sees how quick it is to cut something so precise, their mind will be jumping from idea to idea, ready to work.

Demo Time

If you need to put on a quick demo or plan a larger workshop to reach a wider community audience, you are in luck! Laser cutters are far superior for events compared to 3D printers or most other tools. Here’s why: With only one cutter, along with the right materials and some patterns, you can handle a hands-on class size of fifteen excited individuals in under two hours. Compare this to hosting a workshop of 3D printing for the same class size you will encounter the need for at least five printers, not to mention all the preparations required for each.

In each case, file preparation is made easier with online repositories. Simple laser cutting patterns can be found online at Vecteezy and other sites. Copy over your downloaded, or originally designed, SVG, AI, or EPS file to the machine, and away you go.

Practical Things

Laser cutters excel at helping you produce objects quickly and precisely. You do not need the hand skills of a traditional craftsman, nor knowledge of any complicated software. Cutting with precision allows you to explore ideas on a variety of materials, and iterate those ideas quickly.

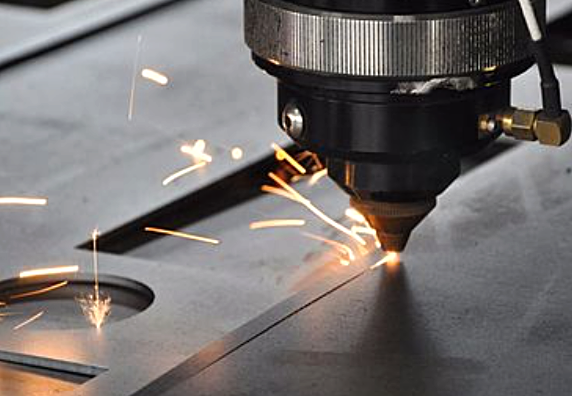

Most cutters can cut or engrave upon wood, metal, plastic, cloth, leather, and many many more materials. Not only can you cut, but you can etch, too, allowing you to transfer traditional (raster) digital images, as well as vector (paths) shapes. Thinking about making a custom leather bookmark for an avid reader? No problem. Interested in producing a custom stencil set? No problem. Want to put text or logos on your favorite travel mug? No problem. Laser cutters can do it.

Make It for Real

Best of all, many laser cutters scale! Unlike the build-plate limitations found with 3D printers, many laser cutters allow users to feed bigger materials than the bed through the machine. When you finish designing and iterating your small pattern, scale it up to life-size.

All this to say, laser cutters rock, and you should seek one out and exploit their value. They are a great investment for makerspaces and a significant investment of your creative time. Now get out there, get cutting, & scale it up!

About LIGHTS: Ohio University’s Innovation Center founded the LIGHTS (Leveraging Innovation Gateways and Hubs Toward Sustainability) program in 2016. LIGHTS’ Innovation Network catalyzes the creation of companies to create high-wage jobs, and attract greater private investment in the coal-impacted regions of Ohio, West Virginia, and Kentucky. The Appalachian Regional Commission generously funded the program because of its unique way of matching complex problems and opportunities facing corporations, communities, and individuals to a network of two strategically-placed Innovation Hubs and seven Gateways. New marketable products arise from these problems. The Gateways and Hubs are new business incubators and makerspaces serving a 28-county area.